Types and Specifications of Strain Gages

Type numbers of strain gages are determined in accordance with individual meaning in specifications of respective strain gages. - Click here -

Although there are many machineries and struactures in which we are now living for carrying out a modern social operation, we will not be able to keep a life smoothly and safely unless functions or safety of these facilities be fully ascertained. Strain gages have developed and widened the scope of their application as one of the most fundamental means to confirm the degree of safety of machinery and structures we are using and also as the sensors to actually detect and measure strains and stress at the spot.The history of these strain gages is considerably long and old and the bonded type strain gages which we are currently using have been designed and schemed initially in 1938 by Simmons & Ruge in America. Our SHOWA Company started manufacture of strain gages for the first place in Japan in 1962 as the foil grid type strain gages. Strain gages are really indispensable means to detect strength and properties of metals, rubber, plastics, ceramics which we are using in our daily life.

Type numbers of strain gages are determined in accordance with individual meaning in specifications of respective strain gages. - Click here -

Patterns and Specifications Table of Strain Gages. - Click here -

| Kinds | Uniaxial Strain Gages | Biaixal Strain Gages | Triaxial Strain Gages | Stress Concentration Measurements |

|---|---|---|---|---|

Pattern Code |

N11... | N22... | N32... | R11,N51,R51... |

Lead wire pre-attached |

N11...VS... | N22...VS... | N32...VS... | R11,N51,R51...VS... |

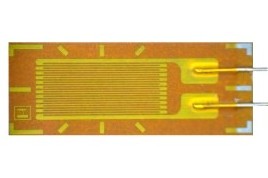

Basic pattern |

|

|

|

|

| Kinds | Uniaxial 45° | Diaphragm Type | Crack Detection | Pipe Gage |

|---|---|---|---|---|

Purpose |

Shearing stress and torque measurement | Pressure sensor | Crack propagation detection and analysis | Bolt spindle power measurement -Click- |

Pattern Code |

Z11,Z23... | Q44... | X11,C11... | P11... |

Basic pattern |

|

|

|

|

Can comply with requirements to be extended to custom built strain gage pattens for sensor applications. - Click here -

Foil type terminals with glass-epoxy supporting base are ready. - Click here -

We have provisions of adhesives for instantaneous bonding, ambient temperature hardening type, hardened type with heat applied, and so on. - Click here -

Waxes, silicone rubber, and putyl rubber series coating materials are prepared in our stock. - Click here -

In order to obtain the best possible results from a strain gage installation... - Click here -

Utilize the following factors as the fundamental information in regard to measurements by means of strain gages. - Click here -

Refer to the following expression for knowing errors taking place during strain measurement. - Click here -

Home | About Us | Contact Us | Site Map... | tuochi Automatic Instrument Co.,Ltd Tel: 021-51085998 Fax: 021-51069009 Mail: zhang@yanatoo.com